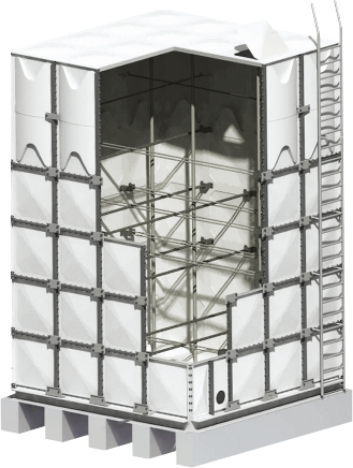

| Name | Manway panel |

|---|---|

| Material | GRP |

| Name | Manway panel |

|---|---|

| Material | GRP |

| Name | External Ladder |

|---|---|

| Material | GRP |

| Name | Internal Ladder |

|---|---|

| Material | GRP |

| Name | Internal Tie-Rod |

|---|---|

| Material | GRP |

| Name | Internal Bracket |

|---|---|

| Material | GRP |

| Name | Sealing Tape |

|---|---|

| Material | GRP |

| Name | External Bracket |

|---|---|

| Material | GRP |

| Name | Corner Bracket |

|---|---|

| Material | GRP |

| Name | Bottom Bracket |

|---|---|

| Material | GRP |

| Name | Corner Frame |

|---|---|

| Material | GRP |

| Name | Roof Support |

|---|---|

| Material | GRP |

| Name | Base Frame |

|---|---|

| Material | GRP |

| Name | Bolts and Nuts |

|---|---|

| Material | GRP |

| Name | Sealant Right Seal |

|---|---|

| Material | GRP |

| Name | Water Level Indicator |

|---|---|

| Material | GRP |

| Name | Name Plate |

|---|---|

| Material | GRP |

| Name | Manhole |

|---|---|

| Material | GRP |

| Name | External Ladder |

|---|---|

| Material | GRP |

| Name | Internal Ladder |

|---|---|

| Material | GRP |

| Name | Corner Frame |

|---|---|

| Material | GRP |

| Name | Bolts & Nuts |

|---|---|

| Material | GRP |

| Name | EPDM Right seal |

|---|---|

| Material | GRP |

| Name | Roof Tie-Rod |

|---|---|

| Material | GRP |

| Name | External Frame |

|---|---|

| Material | GRP |

| Name | Roof Support Pipe |

|---|---|

| Material | GRP |

| Name | Corner Bracket |

|---|---|

| Material | GRP |

| Name | Water Level Gauge |

|---|---|

| Material | GRP |

| Name | Base Frame |

|---|---|

| Material | GRP |

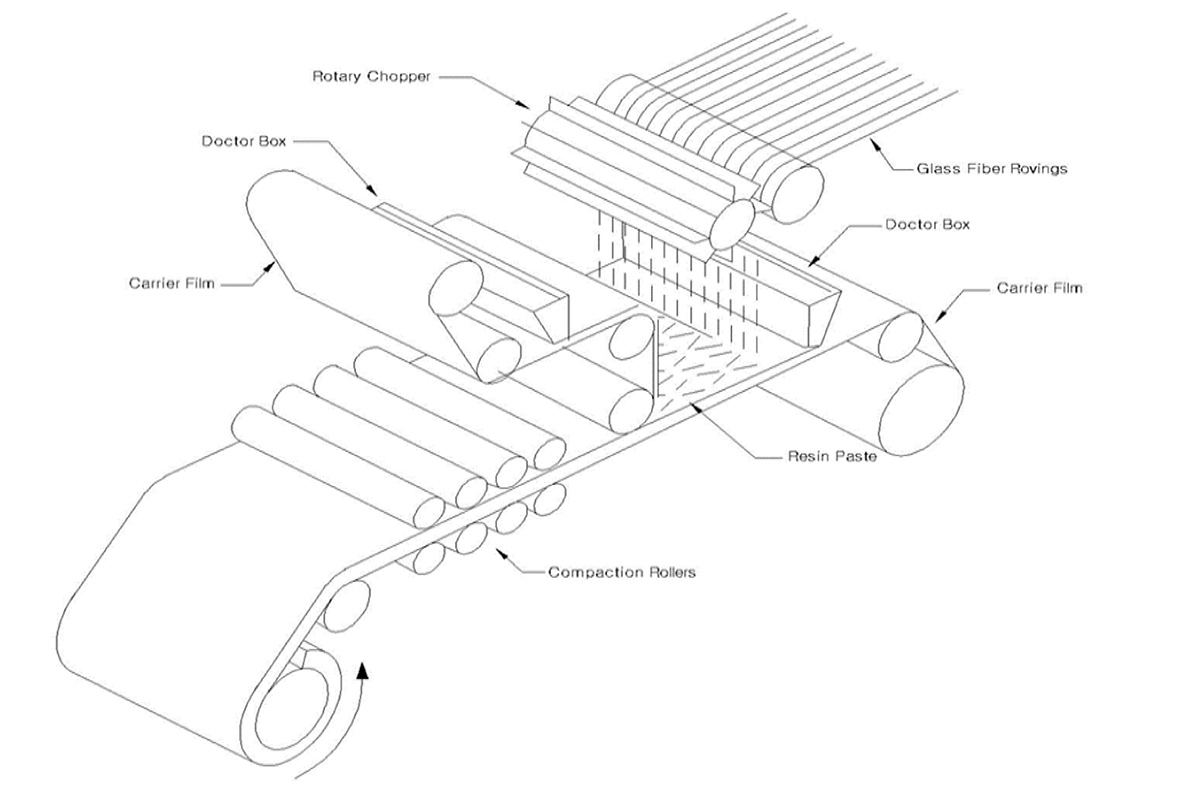

A release agent, a diluent, a hardener, a polymerization inhibitor, and a thermoplastic in an unsaturated polyester resin that is a thermosetting resin a pigment and a thickener are added while maintaining a certain degree of viscosity by mixing a water storage agent and a dispersant.This compound is aged to the target viscosity with SHEET made by forcibly impregnating glass fibers 1 inch apart It refers to a method made by creating a semi-solid state and compressing and molding it into a large hydraulic press at high temperature and high pressure.Current scope of application includes water tanks, bathtubs, waterproof plates, automobile parts, doors, manholes, exhaust ports, and electrical insulation cases It is used in various fields of industrial building materials.

S.M.C Manufacturing Process

S.M.C Manufacturing Process

GRP Water Tank

GRP Water Tank

Car Frame

Car Frame

Bathtub

Bathtub

Wind Power Generator

Wind Power Generator

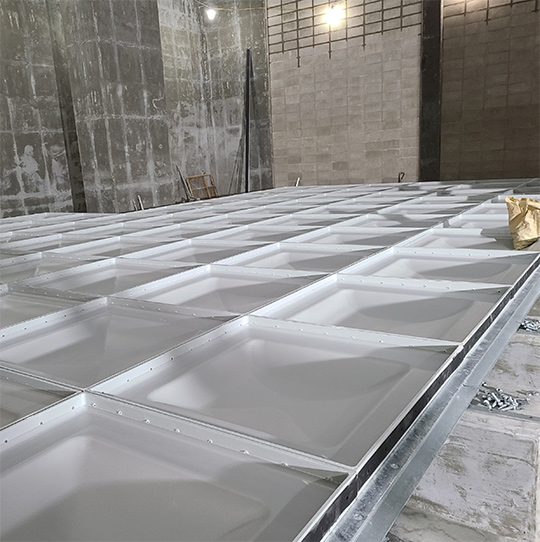

Wall Panel

Flat Panel

Bottom Panel

Roof Panel

Drain Panel/ Manhole Panel

| Item | Unit | Physical Properties | KS Standard |

|---|---|---|---|

| Gravity | 1.85 | - | |

| Tensile Strength | MPa (Kgf/mm²) |

102.9(10.5) | 60(6.12)↑ |

| Flexural Strength | MPa (Kgf/mm²) |

151 | 80(8.16)↑ |

| Flexural Modulus |

MPa (Kgf/mm²) |

17.100 | 6,000(612.24)↑ |

| Absorption | % | 0.06 | 1↓ |

| Barcol Hardness | - | 58 | 30↑ |

| Glass Fiber Content |

% | 31 | 25↑ |

| Thermal Conductivity |

- | 2.0 × 105 | - |

| Distortion | - | 2.0 × 105 | - |

※ The above mentioned data are subject to change depending on the testing conditions and environment.

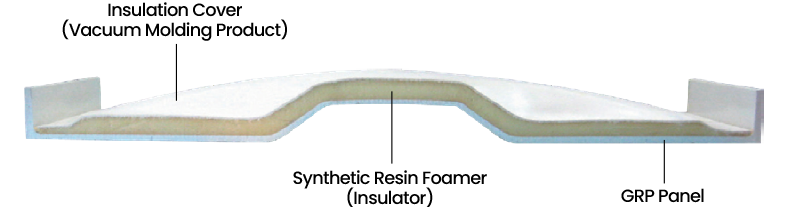

GRP insulated panels are made from applying polyurethane, an efficient insulator on a single-layer panel, and covering it with a special synthetic resin foamer, creating a sandwich-like structure panel with high insulation performance.

GRP water tanks have outstanding insulation and dew-proof as triple sandwich structure. Because single panel with heat retention which has 250 times conductivity more than other metal (STEEL, SUS etc) is laid, and polyyurethanes foam with excellent insulation effect is inserted as lagging. Lastly special cover made of synthetic resin vacuum-molded is put on.

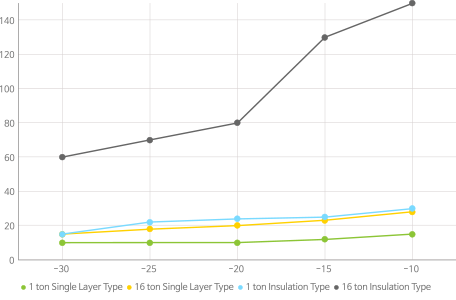

Temperature of atmosphere

During the time when the water temperature

decreases from 5°C to 0°C

SLS Certificate(SS245)

EPDM Right Seal

Thickness restored by 98% after 24hours of applying EPDM Right Seal

Image of a corner type

Corner ㅁtype

Corner ㄴtype

Cube type

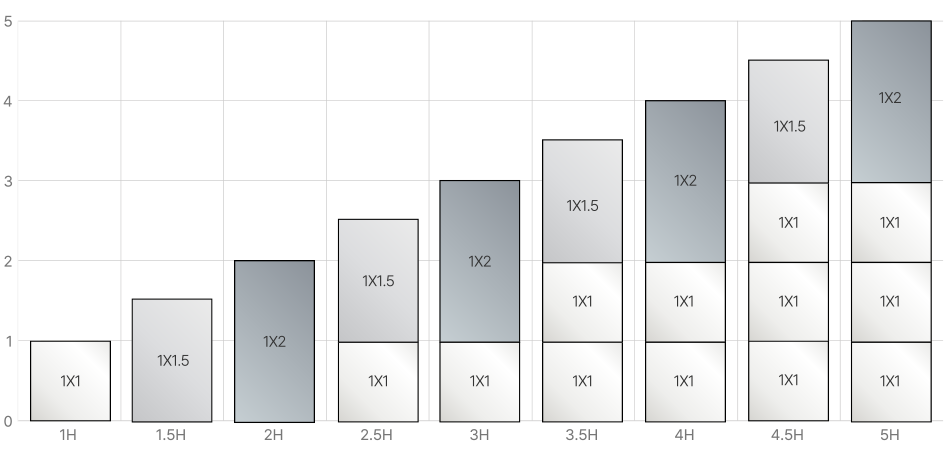

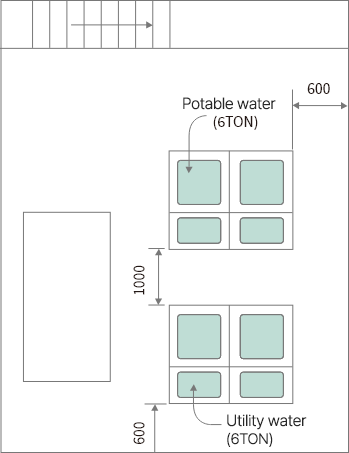

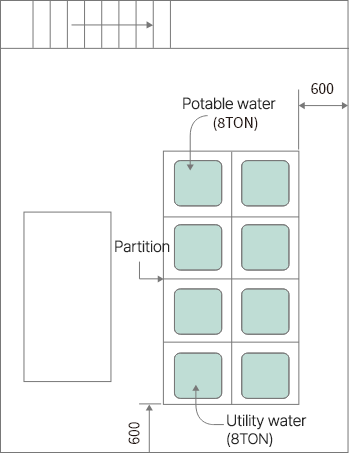

One water tank in a limited space creates an effect of installing multiple tanks, which is an economical alternative and efficient for maintenance.

If tanks for two different use are needed in a limited space of area or a boiler room, a 16-ton partition type tank can be installed to use half for potable water 8ton and the other half 8ton for ytility water. 8ton however, if two separate tanks are installed instead, it needs 1 meter distance between the two tank. So each tank capacity is only 6 ton.

1.5m × 2m × 2m = 6ton

2m × ( 2m + 2m ) × 2m = 16ton

ex) 3W × 4L × 2H

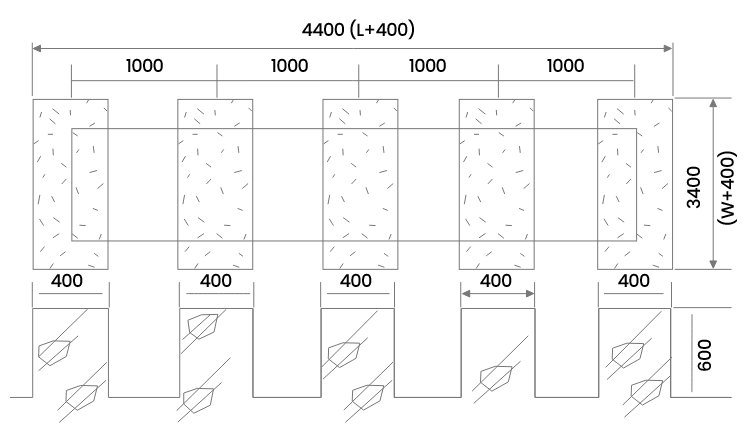

※ SMC water tanks are recommended to be installed indoors for freeze prevention and maintenance.

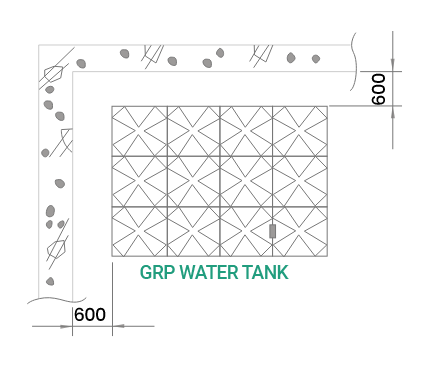

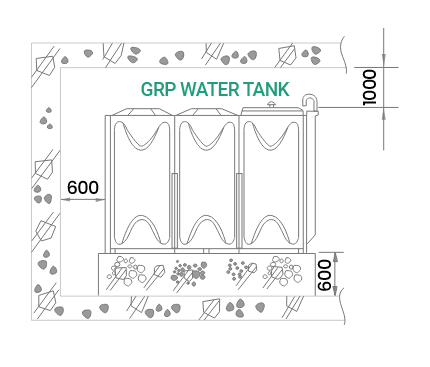

For installation and maintenance of water tanks, the tanks require an extra space of at least 600mm on each side and 1,000mm to the ceiling.

Floor plan

Side view